- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 77 Author: Site Editor Publish Time: 2023-02-03 Origin: Site

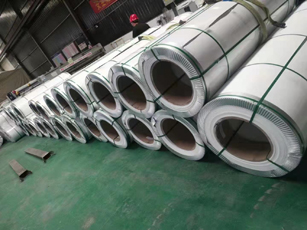

Fiberglass Sheet, known as FRP sheet or GRP sheet, is Fiberglass Reinforced Plastic. It is a composite material made by combining fiberglass and unsaturated polyester resin. The fiberglass provides the strength and stiffness, while the resin binds the fibers together and protects them from the environment. This combination of materials results in a lightweight and strong product that is resistant to corrosion and damage from environmental factors such as moisture, temperature changes, and UV light. We produce and supply the FRP sheet either in cut to length sheet form, or in FRP rolls. This brings more flexibility to customers, as they can choose the way that is more convenient for their uses.

Width | 1220mm, 1500mm, 1800mm, 2000mm, 2300mm, 2500mm, customized widths within 3200mm |

Length for sheets | 2440mm, 3000mm, 4000mm, 5800mm, or cut to length within 11800mm |

Length for rolls | From 60meters to 120meters. Customized length of each FRP roll available |

FRP sheet thickness | 1mm, 1.5mm, 2mm, 2.5mm, 3mm or any customized thickness within 5mm |

GRP sheet surface | Gel coat & non gel coat optional |

Surface options of FRP sheet | Smooth surface, embossed surface (pebbled surface) |

Fiberglass types | Chopped strand fiber, woven roving, double woven roving |

Type of resin | UPR (unsaturated polyester resin) |

Gloss options of GRP sheet | Matt finish, high glossy finish |

Color options of FRP sheet | White, Grey, Red, Yellow, Black, Blue or customized color matching |

Non gel coat |

Gel coat |

Embossed white |

Embossed black |

Various colors |

Fiber Reinforced Plastic (FRP) sheet and fiberglass sheet roll are available in several types, based on the type of fiberglass used in their production. The following are some of the most commonly used fiberglass types for FRP sheets:

Chopped Strand Fiber: Chopped strand fiber is a type of fiberglass that is made by cutting continuous fiber strands into shorter lengths. These shorter fibers are then mixed with resin to create a mat-like material, which is then molded into the desired shape. Chopped strand fiber is commonly used in the production of FRP sheets for its ease of processing and low cost. Surface of this type of fiberglass sheet is smoother. For this type of frp sheet, it is produced through a continuous mixing and extruding process, and eventually rolled up to be frp roll.

Woven Roving: Woven roving is a type of fiberglass that is made by weaving continuous fiber strands together to form a fabric-like material. Woven roving is commonly used in high-strength applications where the fiber orientation is important for the strength and stiffness of the final product. Our standard production is with one layer of woven roving. In case super high strength is needed, we also offer double woven roving (2 layers) as alternative solution. This type of grp sheet is either produced in roll form, or produced piece by piece through a molding process.

Chopped Strand Fiber |  Woven Roving Fiber |

High Strength: Fiberglass sheets are known for their high strength-to-weight ratio, making them ideal for applications where weight is a concern, such as in the aerospace and automotive industries.

Durability: FRP sheets are resistant to weathering, corrosion, and impact, making them suitable for outdoor and harsh environments. They are also resistant to chemicals and UV light, which helps to extend their lifespan.

Electrical Insulation: GRP sheets have good electrical insulation properties, making them suitable for electrical applications where electrical conductivity is not a concern.

Fire Resistance: When fire resistant is needed, we can use special type of resin to make the FRP sheets complying with fire action Class B1. This type of FRP sheets is self-extinguishing and have low flame spread, making them suitable for fire-resistant applications.

Lightweight: FRP roll are much lighter than traditional materials such as steel and concrete, making them easier to handle and install.

Versatility: Fiberglass sheets can be molded into a variety of shapes and sizes, making them suitable for a wide range of applications. They can also be produced in different colors and finishes to match the specific requirements of the project.

Cost-effective: GRP sheets are typically less expensive than other high-performance materials, such as carbon fiber, making them a cost-effective solution

Item | Unit | Fiberglass Types | ||||

Chopped Strand Fiber | Chopped Strand Fiber | Woven Roving Fiber | Woven Roving Fiber | Double Woven Roving Fiber | ||

Thickness | mm | 1.5 | 2.0 | 1.5 | 2.0 | 2.0 |

Density | g/cm³ | 1.4 | 1.4 | 1.5 | 1.5 | 1.5 |

Weight | Kg/m2 | 2.1 | 2.8 | 2.25 | 3.0 | 3.0 |

Fiberglass content | % | 26 | 27 | 30 | 30 | 31 |

Hardness | Barcol | 40/42 | 40/42 | 40/42 | 40/42 | 40/42 |

Tensile strength | Mpa | 75 | 85 | 105 | 110 | 145 |

Tensile modulus | Mpa | 6230 | 6340 | 7150 | 7420 | 9980 |

Flexural strength | Mpa | 95 | 115 | 150 | 158 | 217 |

Shear strength | Mpa | 75 | 86 | 95 | 100 | 120 |

Fiberglass sheet and fiberglass sheet roll are used in many applications, including for wall covering, door skins, truck body or caravan body manufacturing, roofing, flooring etc. And frequently they are made into FRP sandwich panels with XPS foam or PU foam for incorporating the thermal insulation; or made into FRP honeycomb panels with aluminium honeycomb core or PP honeycomb core for incorporating the high strength while remaining at low weight.

Making sandwich panel |

Making honeycomb panel |

Making truck body |

Making walls |